AUTOMATIC SELF-CLEANING DISC FILTER

Technomax’s distinctively developed disc filtration technology operates using thin, color coded polypropylene discs of a specific micron rating. The discs are diagonally grooved on both sides, in opposite directions. A series of discs are stacked and compressed on a specially designed spine. The stacked discs are enclosed in a corrosion proof and pressure resistant housing.

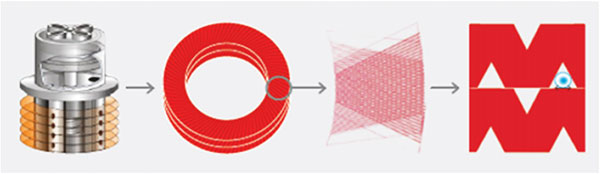

The grooves of any two adjacent discs, pressed together, create a series of crossing points which form multiple particle traps. In the filtration process, the force of the spring along with the differential pressure firmly compresses these discs together providing exceptional filtration effciency. Filtration occurs as water percolates from the outer diameter to the inner diameter of the filter element. Depending on the micron rating, there are multiple crossing points in each track, creating distinctive in-depth filtration.

Standard Features:

Securely stacked discs for micron-precise filtration of solids• Corrosion resistant construction

• Innovative depth-filteration design captures and retains large amounts of solids for longer filtration cycles

• Short, effcient backwash process conserves water and energy

• Easy and simple operation

• Long-term operation with minimal maintenance

Material of Construction:-

Filter shell - Polypropylene

Filter element – Polypropylene

Filter disc - Polypropylene

Flush valve - Polyamide

Solenoid valve - Brass

Exhaust valve – Polyamide

Piping System – Polyamide

Diagonally Grooved Disc Filtration

Filtration Process:

The color coded micron sized filtration discs are stacked on the Central spine and assembled according to predetermined water filtration requirements. During filtration, the discs are compressed by means of preloaded spring and differential pressure, forcing the water to pass through the grooved discs surface, thus trapping the solids.

Backwash Process:

Activated by a predened time command or differential pressure, the system enters backwash mode. The inlet valve port shuts as the drain port opens. During the backwash process, pressure is released and the spine’s piston rises, releasing the compression on the discs. Tangential jets of clean water are then forced through the nozzles positioned along the spine. At this stage the discs spin freely, loosening the trapped solids which are then ushed out. During this time the other modules continues to give ltered water downstream. Backwash time of each pod is 20sec.

AUTOMATIC WATER FILTRATION SYSTEM